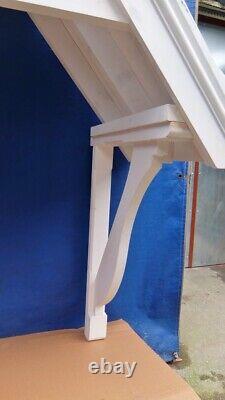

Door Canopy Porch Cover Rain Awning Timber Wooden Gallows Bracket CAN3 2175x1915

Door Canopy Porch Cover Rain Awning Timber Wooden Gallows Bracket CAN3 2175x1915. Outside of gallows brackets is 1590mm with the inner being 1400mm. Overall height of 2175mm, the gallows brackets are 1050mm. Depth from the wall is 760mm. Heavy duty frame section as been used. You will need to supply your own roof tiles or felt.

In stock ready for quick dispatch, collection is welcome. This item can be delivered using the service detailed below. Please include a house number if your address has one.

If you (or someone representing you) is not prepared to. We will only ever request the below surcharges if they are required, and we keep them to the minimum level possible based on the final weight of the consignment and your postcode. The delays stated are the worst case scenario and we always aim to better these, but cannot guarantee this. Standard cost as per listing, no surcharge. Cannot be delivered on this service. Note, this does not apply to multiples of the same variation or product. We use several courier services, which are dependent on the type of goods you are ordering. This service is provided by Evri. Generally this is used for unglazed items. This service is ideal for glazed or more delicate items. We also use this for larger items which are difficult to transport. If you order several items, across several different services, please leave a note at checkout and we will combine them onto the largest appropriate service and charge it according to the final combined weight. We do try to keep a lookout for combinations, but leaving a note makes sure your combination is not missed. The below instructions are for all deliveries and is the best practice for receiving them, but is most important for the 24hr and other 5 day courier services. This is VERY important because, if you sign for 3 items and only 2 are present, on paper 3 have been delivered and the courier will refute any claim against them. Check all your items have YOUR details on them. Courier drivers have been known to mix up items, so this is also VERY important.When the goods arrive, give them a good visual check over, looking for any evidence that the packaging is damaged. This act means that the courier is liable for any damage to the item and helps speed up any replacements or a resolution. Then should you open the goods to find the item is damaged, you are covered.

We package items very well, so 9 times out of 10 the goods will be fine, but by doing this you have protected yourself inline with the couriers terms and conditions. We give 48 hours to identify damage or incorrect items and report it. It is also very prudent during this step to double check the items will fit where intended before removing any existing joinery, glass or decor.

This is done strictly AT YOUR OWN RISK, as the courier classes this as a clean signature. If they decide not to do so, there is little we can offer to compensate you. In the case of the 24 hours courier, when no note is left, they may do one of a few things. Leave your goods with a neighbour if one is willing to take the items.

This is not ideal as your neighbour will not be vigilant in checking for damage and is likely to just sign for it clean. If the driver thinks it's safe to do so, they may simply leave the goods at your property without a signature. In todays day and age more and more items are being left without customers present to sign for them. Also, even after following the above instructions you may open up your items to find some damage.The following is what to do in this instance. Provide photos of the damage and packaging damage. We will usually respond within 24 hours, with the exception of weekends. Some of the items we sell are one offs, such as made to measure items or one off windows, so in the instance of these we cannot offer a replacement.

NOTE: Replacements can only be sent free of charge if you have declared the item'damaged' on the couriers note. We reserve the right to refuse or charge for replacements if these steps have not been followed. We cannot be held liable for any costs incurred by goods arriving late or damaged. We can only apologise if this is the case, and is usually when the courier has had a mix up on route.We sell glass packs for our windows and doors, so below is a guide on how to handle it. Glass is usually supplied loose from the item, so you need to know how to handle and store it.

The glass is usually delivered bubble wrapped or similar. DO NOT leave the glass in this wrapping. It is only for transport. If double glazing is left in the wrap, particularly in hot or rainy weather, it can trap water or heat having a detrimental effect to the hot melt seal of the double glazed units.

Always stand the glass on edge, leant against a wall. Always protect the first piece that is leant against the wall, e. With vertical timber laths, or a sheet of ply. Always put glass onto timber laths, equally spaced for the piece of glass, so the weight is evenly distributed.Never put the glass down directly onto concrete, or other hard flooring, as this will break the glass. When leaning one glass piece onto the next, always make sure the pads stuck to the glass are between them. Never put glass to glass directly. Avoid putting glass on the corner as this could break the unit, even if it is toughened.

Always put the glass down squarely on the edge. One small knock on a corner of glass can shatter it. When moving the glass, please make sure that you are only picking up what you intend to. The glass can stick to the pads, or can be stuck through suction, e.

This will then drop when the glass loses its grip and could smash. Once signed for, the glass is your responsibility, so please follow this guidance. If you choose collection for your item(s), you can collect between 8am and 4:30pm Monday to Friday, and 8am to 12:30pm on a Saturday. We will require 24hrs notice of weekday collections, or 48hrs for Saturday collections, as some goods are stored off-site. If you are travelling over distance to collect, please ensure you allow adequate time for loading up the goods and any traffic as the collection times are strict and you may be turned away if you are not within the times stated.Please Note: We do not wrap items which are for collection. Please remember to bring any packing or protection with you to ensure they do not get damaged in your vehicle. Please check the items will fit in your vehicle before travelling. To Consider: When you collect your goods, please ensure they are correct before leaving the store.

When you collect your items, if there is a problem with them, you will be responsible for returning them, even if they are incorrect on our part. We have summarised this below.

We can organise this, but the cost would have to be paid before collection is made. Alternately and preferably, you can organise this for yourself. Made to Measure or Cut Items.

We would then communicate our intensions, based on the item cost, damage extent and nature of the item. Its very important that you consider this step before you get your goods.

The longevity and performance of timber products is directly related to how well you treat and maintain the treatment. What you need to do to it for treatment will depend on several factors, such as if its internal or external, what the desired end appearance is and also the type of product you are treating.

Certain products are made in such a way that a particular treatment type is required. A really good example of this is engineered doors which, in the main, require oil based treatments be used. If the product comes with treatment instructions either with the product, or has it specific treatments stated in the item description, then that MUST be followed. If there are no specific requirements, then you must treat your product according to its end use and position. Below is a generic guide of good practice for treating timber products followed by a specific guide for engineered/veneered doors.

It is always better to fully treat items before they are fitted. This allows areas which will be concealed, such as glazing rebates, to be fully painted. For a timber window, you will need external treatment.

Always read the instructions on the tin. Usually, if you are using a paint or stain "system", the top coat instructions will contain details of any recommended basecoats, preservers, fillers etc. Its prudent to use the full "system" so you know all items are compatible.

It will also tell you the correct application equipment (roller, brush type etc), so you know the correct method to use it. Be wary of using dyes, waxes and oils. These are usually only suitable for internal solid timber items.

Dyes in particular are just a colourant and do not offer any protection against moisture or dirt ingress so always need to be overcoated with a final finish of some description. Make sure you have a clean, dry and well ventilated area to carry out preparation and treatment.

Ensure you try and have everything to hand you may require before commencing. Prepare the item first by carrying out any filling required, sanding and brush down the item to remove any dust. Try to remove any visual areas of markings out, discolouration, grease or other dirty marks. Particularly with external products, make sure any gaps or joints are filled/sealed against moisture ingress.

Clean down the item with a suitable cleaner, usually something like Methylated spirits, to remove any residual dirt or contaminants that may affect the finish. Its usually best to use a lint free cloth or rag for this process. If you are painting the product, and the product contains knots which may bleed, you will need to apply knotting solution or a stain blocking primer. Certainly, if you are painting an Accoya item, stain blocking primers are a must.

Make sure you fully stir the treatment to distribute the pigment and solvent to ensure an even coat. Give a light rub down between coats of paint to de-nib and ensure maximum adhesion. It is always best practice to completely treat all areas, edges, behind ironmongery and within mortices to ensure full protection. This usually means the door has a mixed timber core, which is then veneered and lipped in the face timber e.When a door is made like this, it is invariably tested with certain finishes. For instance, you will see in some of our item descriptions that only oil based (often referred to as solvent based) paints should be used. Another common one is that "high-build" finishes should be used. It is vitally important that you use the correct treatment on engineered doors.

Certainly, 95% of engineered door issues reported to us usually stem from incorrect treatment, so its in your best interest to make sure you are using the correct treatments. As mentioned above, some doors will have instructions within the packaging or item descriptions, and these MUST be followed. Below is a best practice guide, specifically for engineered doors, which is an amalgamation of several suppliers instructions. Do not use water based, low build products for engineered doors.

Anything "quick drying" is usually water based and substandard for engineered doors. Check over, prepare and fully treat the door before fitting. This will highlight any unseen issues before you incur any fitting expenses. The same finish should be used all over the door. For an external door, both sides should be treated with the same external grade finish.Immediately after fitting, you should remove the ironmongery and re-treat anywhere which has been cut, chiselled, morticed or drilled. Make sure all edges and faces are treated after fitting as its very common for your fitter to have to plane those areas.

Always fit 3 hinges per door as a minimum. Most door manufacturers insist on this. Adding a central hinge reduces the chances of a door warping as it is held centrally. Ensure external doors are fitted with the correct drips and weatherboards. For instance, as stable door would require a drip in the centre and a weatherboard at the bottom. We pass this down from our supplier. It is vital, therefore, that you inspect everything thoroughly BEFORE treatment and organising fitting. You need to inspect for things like splits, cracks, poor veneer, marks, water marks, mould, scratches on the glass, movement from the panels or glass and for twist and warp.The item is not entirely treated on all edges, faces and behind fittings. The item has been cut down by more than is recommended. Usually the tolerance is 4mm per edge.

Incorrect treatments have been used either by type (water or Oil based) or for its location (internal or external). As mentioned, this is the single biggest contributor to door issues. You have used an internal door externally, or vice versa. 2 standard doors have been rebated to meet. Usually rebating is cutting a 12mm from an edge partway through. This is over the cutting tolerance. Weatherboards have not been used with an external door.We will also require the details of the treatments you have used. Occasionally, they may want to carry out a site visit, but more often than not, they will process from photos. It needs to be stated that their decision is final and although your contract is with us, we will align our decision with theirs in most cases. It does not cover ANY labour, treatment or transport costs.

We are manufacturers of made to measure joinery items, such as windows, doors, gates, garage doors and stairs. We are a family run timber merchant established in 1974. Based in Sutton-in-Ashfield, we have supplied timber and joinery products to Sutton-in-Ashfield, Mansfield, Kirkby-in-Ashfield, Mansfield Woodhouse, Annesley, Clipstone, Alfreton and other areas surrounding Sutton-in-Ashfield for many years. We now offer this same service nationally using courier networks.

We are a diverse company offering many different products and ranges in addition to our core timber supply business.